CHARACTERISTICS

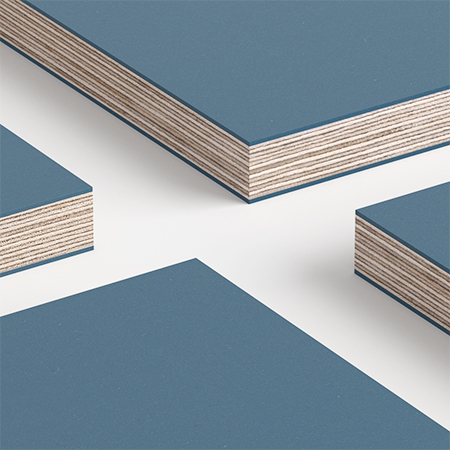

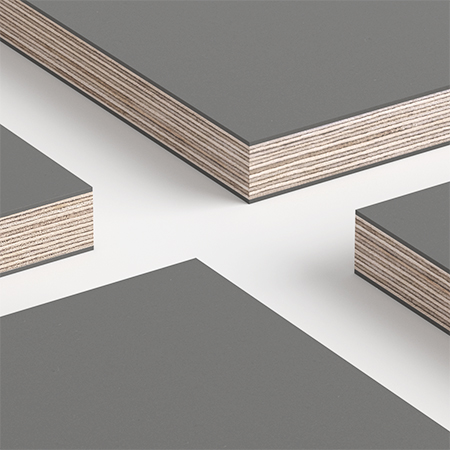

STRATO-STOCK® is a Birch plywood panel with plastic overlay.

- Abrasion resistance is considerably higher

- When nailed, the panel does not splinter

- Cleanable with high pressure water

- The panel’s life is at least four times longer than traditional phenolic plywood

The ILPA company was the first, in 1993, to patent and manufacture this new product for the concrete formwork industry. Subsequently, using specific “joint development programmes”, it patented and made further versions, such as the Xlife panel.

STRATO-STOCK® panel is compatible with all formwork systems available on the market.

Ultrasound control

The bonding of each single STRATO-STOCK® panel is regulated by ultrasonic machinery.

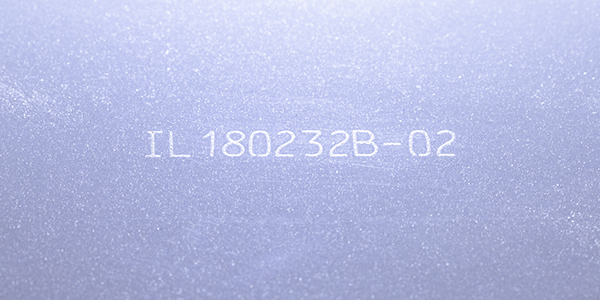

Laser screen printing

Afterwards, the panel is marked on the rear with a laser screen printing which guarantees traceability.

Traceability

The panel can be easily traced thanks to a label showing the barcode and lot number.

Application of STRATO-STOCK® panel in the frame.

MECHANICAL RESISTANCE

The impermeability of the product keeps the original mechanical characteristics of the wood stable over time, avoiding a rapid deterioration.

| Thickness EN 315 | mm | 9mm 8,59,5 | 12mm 11,312,5 | 15mm 14,215,3 | 18mm 17,118,2 | 21mm 19,821,1 |

| Bending Resistance EN 789 | MPa | 59 | 58 | 41 | 40 | 50 |

| Elastic-Modulus EN 789 | MPa | 4'100 | 4'500 | 5'600 | 6'000 | 7'300 |

| Plies | n° | 5+2 | 7+2 | 9+2 | 11+2 | 13+2 |

| Weight | kg/m2 | 7,5 | 9 | 11,5 | 13,5 | 15,5 |

HIGH ABRASION RESISTANCE

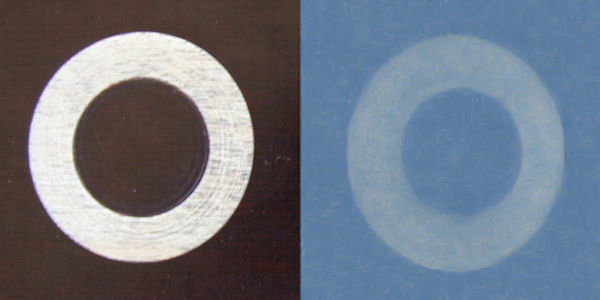

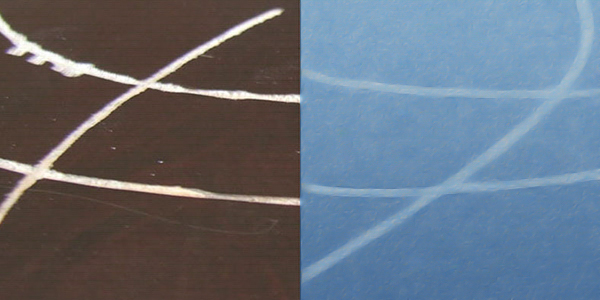

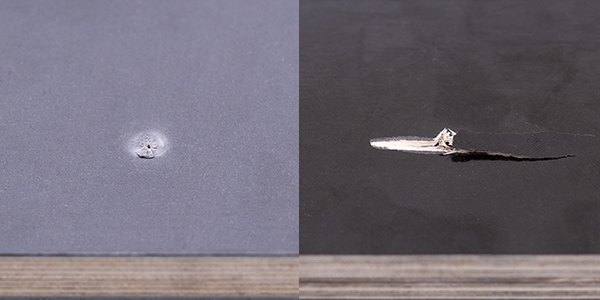

The images demonstrate the performance of both STRATO-STOCK® and film faced plywood subjected to both a scratch and taber stress test. STRATO-STOCK® panels do not fear heavy abuse.

Taber test

Scratch test

Technical Features of External Overlay

| Surface Material Water Absorption | < 3% | ISO R62 |

| Surface Hardness | SHORE D>70, GARDNER 5, JANKA 5,345 | Catas |

| Abrasion Resistance cs17 500 g 10.000 revolutions | -0,25 g -0,14 mm | CS17 Solvay Lab. |

| Taber Abrasion Resistance | 17.000 revolutions | UNI 9115 DIN 68861/2 |

| Surface Material Burning Resistance | 23 mm/min | DIN 75200 |

| Salty Fog Resistance | The panel doesn’t show any alterations | DIN 50021 ISO9227 |

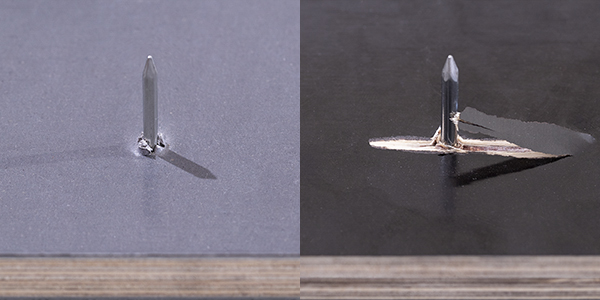

NAILABILITY

The images show the nailability of the STRATO-STOCK® panel and the absence of splintering, which is common in phenolic film faced plywood.

Nail

Surface

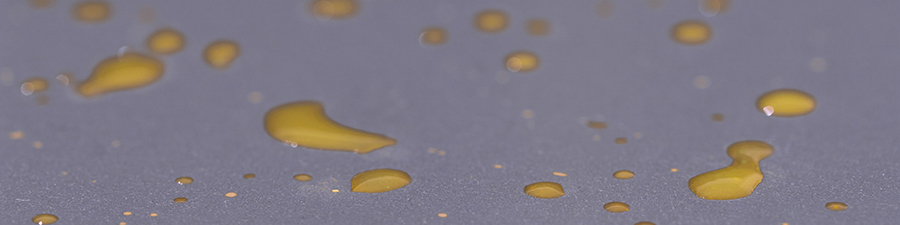

EXCELLENT RESISTANCE TO CHEMICAL AGENTS

Thanks to its polypropylene based surface, the panel resists cement alkalis and other corroding agents.

APPLICATIONS

RECYCLABLE

The STRATO-STOCK® panel consists of a birch plywood core overlaid with a polyolefin based plastic sheet. A study has shown that it is possible to re-use the STRATO-STOCK® panel at the end of its lifecycle. The panel, ground down with other materials, has been used as material to manufacture some products as shown below, injected with an open mold using Plastech technology (read more).

1. The panel

2. Manufacturing

3a. Example of a derivative product

3b. Example of a derivative product